Semi-Tractor Diagram: A Comprehensive Guide

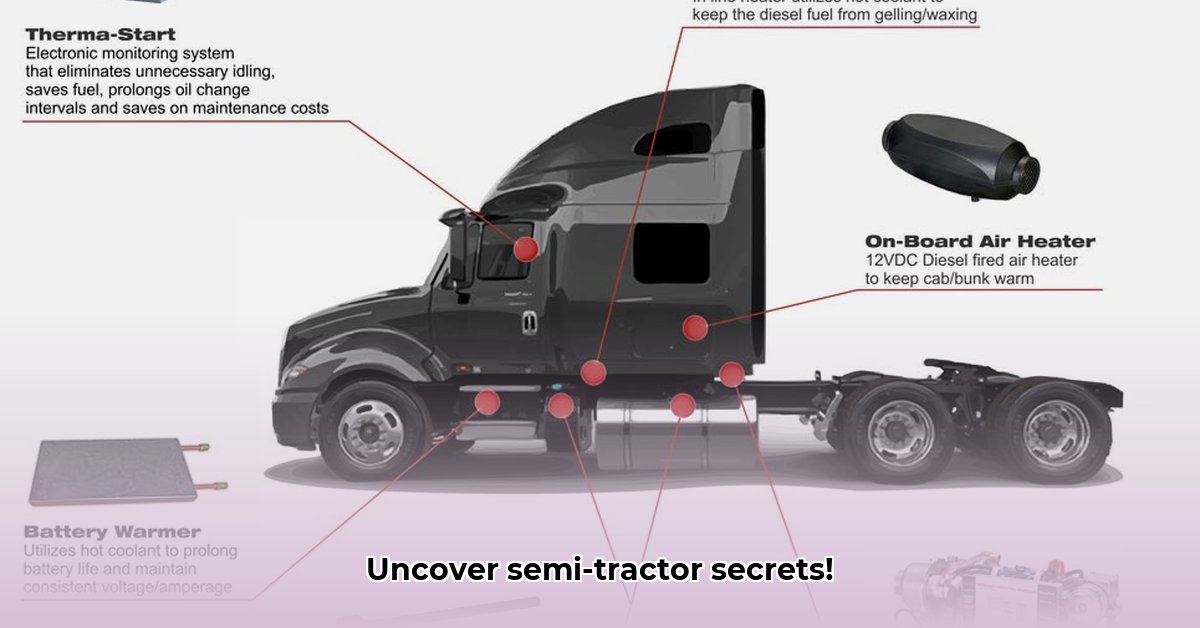

Understanding a semi-tractor diagram can seem daunting, but with this guide, you'll quickly grasp the key components and their functions. This detailed walkthrough is designed for everyone, from seasoned mechanics to those with limited mechanical knowledge. We'll break down the complexities in easily digestible steps, using clear language and helpful visual aids (imagine cutaway illustrations would be included here). Ready to unlock the secrets of these highway giants? Let's begin! For more on semi-truck weights, check out this helpful resource: Semi-Truck Weights.

Did you know that the average semi-truck engine produces over 400 horsepower? This incredible power is necessary to efficiently move heavy loads across vast distances.

- The Engine: The Powerhouse (Diesel engine – the heart of the semi-truck)

The engine, typically a powerful diesel engine, is the primary source of power. Its location, usually towards the front of the vehicle, is clearly indicated on any semi-tractor diagram. Different engine types offer varying levels of horsepower and fuel efficiency, carefully selected to match the truck's intended use. Think of the engine as the truck's powerful, ever-working heart.

- Transmission: Smooth Power Transfer (Gearbox - connecting engine to wheels)

The transmission acts as a gearbox, efficiently transferring power from the engine to the wheels. Its strategic placement, clearly shown in any detailed diagram, plays a vital role in smooth acceleration and efficient speed control, even under heavy loads. Modern trucks frequently utilize automated manual transmissions (AMTs), offering smoother shifts and reduced driver fatigue.

- Axles and Suspension: Stable Support (Shock absorbers & structural support)

Axles and suspension systems are integral for stability and load-bearing capacity. A comprehensive diagram will highlight their design, showcasing how these components support the incredible weight. These act as the truck's shock absorbers and primary support structure, critical for maintaining balance, especially when fully loaded or navigating varied road conditions. Different suspension designs cater to various needs—some prioritize long-haul highway driving comfort, while others enhance stability for off-road or heavy-duty construction applications.

Do semi-trucks really need such complex braking systems? Absolutely! The sheer weight and momentum necessitate a highly effective braking system for safety.

- Brakes: Safety First (Air brakes; Anti-lock Braking System (ABS))

Safety is paramount, and the braking system is a key area highlighted in every reliable semi-tractor diagram. It’s not a single component, but a sophisticated network working in unison. Air brakes, known for their high stopping power, are standard in most semi-trucks. Anti-lock braking systems (ABS) are also crucial, preventing wheel lock-up during emergency braking and helping maintain steering control. Understanding this system’s complexity emphasizes the importance of routine maintenance and inspections.

- Steering System: Precise Control (Typically hydraulically assisted)

Despite its size, a semi-truck requires precise control. The steering system, usually augmented by hydraulics, allows for smooth turns and accurate maneuvering even at high speeds or in challenging conditions. You'll find it near the front of the diagram. System responsiveness varies depending on specific components, directly influencing how a driver interacts with the truck. Continuous research focuses on improving driver response and fuel efficiency.

- Electrical System: The Nervous System (Powering all electrical components)

The electrical system acts as the truck's "nervous system," powering everything from lights and wipers to the sophisticated engine control module (ECM). A full diagram will meticulously illustrate how this network integrates all systems. Problems in this system can trigger broader issues and necessitate regular checks.

- Fuel System: Powering the Journey (Fuel tanks, pumps, and lines)

Fuel delivery is critical, and the fuel system—tanks, pumps, and lines—ensures the engine receives a constant fuel supply. The number and size of fuel tanks determine the range, directly affecting operation uptime and minimizing the risk of breakdowns.

- Cab and Frame: Driver's Space and Structural Integrity (Driver protective area; structural support)

The cab safeguards the driver, while the frame provides overall structural support. A good diagram clearly shows this crucial relationship. Materials and construction techniques influence the truck’s durability, weight, and safety.

- Exhaust System: Emission Management (Managing exhaust fumes)

The exhaust system, usually positioned towards the rear, handles combustion waste products. Its design plays a crucial role in managing emissions and minimizing environmental impact. Ongoing research focuses on improving efficiency and reducing emissions.

Pivotal Points to Remember:

- Safety: The braking and steering systems are critical for safe operation.

- Efficiency: The engine and transmission work in tandem for optimal fuel economy.

- Durability: The frame and suspension ensure long-term structural integrity under heavy loads.

This comprehensive guide, coupled with a well-annotated semi-tractor diagram, equips you with a detailed understanding of these powerful machines. Remember to always prioritize safety and proper maintenance for optimal performance and longevity.